We provide a wide range of branding and decoration options for our promotional products:

Pad Print

Pad Print is a process in which a plastic, metal, silicone, or wooden item can be decorated. The image is transferred from ink filled etched images in a printing plate to the product by way of a silicone pad. While transferring the image to the product, the silicone pad wraps around or takes the shape of the product without distorting the image. Pad printing normally take up to 3 – 4 spot colors (Pantone Solid Coated Inks). It is one of the most common and cost-effective promotional products print methods. Common uses of pad printing: pens, mugs, drink bottles, key rings, stress shapes, etc.

Screen Print

Screen Print, also known as silkscreen printing is a printing technique that uses a porous mesh screen that has an ink blocking stencil transferred onto it. The stencil creates blocked and open areas in the screen that allows ink to flow through them and onto a substrate. Nearly any single ink image, logo or design can be transferred onto a screen. Additional colors require new screens. Screen printing normally take up to 2 – 3 spot colours (Pantone Solid Coated Inks). Common uses of screen printing: bags, umbrellas, apparel, drink bottles, etc.

Rotary Screen Print

Rotary Screen Print is very similar process to the standard above screen printing method. A porous mesh screen is made with your custom stencil design transferred onto it. The difference between a screen print and rotary screen print is the rotary machine will turn the wheels the product is laying on, making the product rotate 270 degrees as the machine presses the screen logo onto the product. Rotary screen print can only be performed onto flat round surfaces. Rotary screen print normally take up to 1 – 2 spot colours (Pantone Solid Coated Inks). Common uses of rotary screen printing: drink bottles, mugs, tumblers, etc.

Laser Engrave

Laser Engrave is often found on wood, acrylic, textiles, stainless steel, or glass products. The engraving method requires no consumables such as inks and is fast with very little setup time. Therefore, a lot of products with personalization (variable data) can be laser engraved. Since the logo impression is physically on the item, the “imprint” will not scratch off and is long lasting. Common uses of laser engrave: metal pens, stainless steel mugs, glass candles, wood, or bamboo pens, etc.

Direct Digital

Direct Digital is used when a logo contains many colours. This process does not use screens as the machine prints directly onto the item but can only be printed onto flat hard surfaces. Digital printing is also referred to as CMYK printing. Since there is no screen involved, there is less setup and therefore works well for small quantity orders. This is machine works slowly, however the drying process is almost instant. Common uses of full colour digital printing: buttons, bags, pens, keyrings, drink bottles, notebooks, etc.

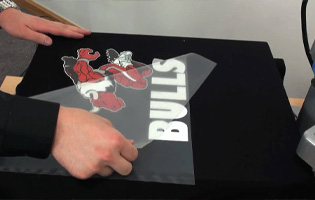

Digital Transfer

Digital Transfer is a process similar to using an iron to press a decal onto a shirt. We use intense heat to press the ink into the material, making sure that your logo isn’t going anywhere. One colour or full colour designs are all possible on heat transfer. Heat transfers are ideal if you have many colours, gradients or small details, but it is printed in CMYK only. We are unable to PMS match. Common uses of digital heat transfer printing: apparel, bags, umbrellas, notebooks, etc.

Embroidery

Embroidery is stitching the logo onto a piece of garment. In the embroidery process, your logo is changed to a digital image comprised of stitches and then assigned colour threads. Then the garment is placed onto the embroidery machine which will execute the digitalized logo into threads. The result is a sophisticated and elegant representation of the logo that is long lasting. Common uses of embroidery: apparel, headwear, bags, etc.

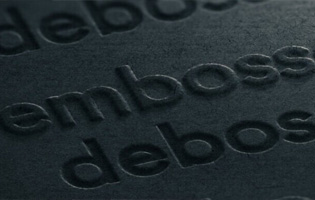

Emboss & Deboss

Emboss & Deboss has been around for a long time. Dies are constructed from metal and in the shape of your logo. The product is then places between them and heat and pressure push to form the material into the impression of what you want. Deboss imprints the logo into the material, whereas emboss imprints the logo to raise out of the material. The result is an elegant logo imprint where you can see and feel the indentation. Common uses of deboss: leather patches, silicone wristbands, PU notebooks, etc.

Digital Label

Digital Label is very similar to direct digital printing, however it is printed onto a white adhesive sticker label then applied onto your product. Digital label printing involves the transfer of the ink directly from the printer head of an inkjet machine to a plain white adhesive sticker label. This process is printed in CYMK only. Only one set up charge is required irrespective of the number of print colours. The machine is slightly slow during the printing process however the drying is basically instant. Common use of digital label: hand sanitizers, tissues, confectionary packets, etc.

Domed Label

Domed Label is a resin coated finish that is produced by printing the artwork onto a vinyl material with strong adhesive on the reverse. The branded area is coated with a crystal-clear resin which is allowed to dry. Once dry, the finished dome decal is applied to the product and the adhesive forms a permanent bond. This process is printed in CMYK, so PMS matching is not possible. Common use of dome label: key rings, notebooks, USB, etc.